Please follow and like us:

**This is a long post (about a 7 minute read). I know some of you found this blog posting by looking for information on “future demand for engineering jobs”. If you are short on time and would just like to get to the actual numbers reflecting future demand and median pay, I have attached a link for you to do so. If you have some extra time, please feel free to read the whole posting and share your feedback. **

It’s always interesting to look at the hard data that is gathered by the federal government on engineering jobs. I have my own assumptions on what seems to be in demand based on my experiences with placing 100s of engineers into jobs.

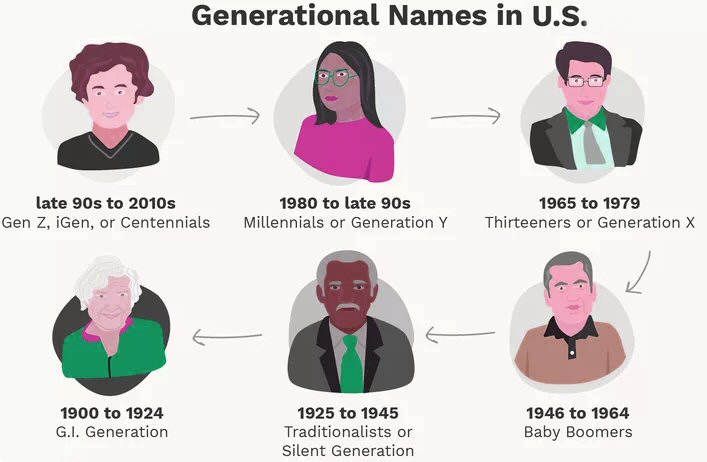

I remember reading about a decade ago that there would be a severe engineering shortage and strong future demand for engineering, due to a shift in the demographics of the domestic population. In essence the baby boomers (born between 1946 and 1964) would be retiring and leaving the reigns to the baby bust generations (genX, genY and eventually genZ)

To some degree this prediction panned out, many engineers are retiring or getting set to retire, but the demographic shift does not explain the demand.

Most of the baby boomer generation, grew up in a different engineering environment. Automation and robotics systems had just emerged and were very limited in the tasks they could do. Most of the plant processes were still very labor intensive and relied on a lot more evaluation of human production vs machine production.

As globalization came to the forefront of manufacturing and engineering, things changed dramatically. Since labor in the global market was much cheaper that put a tremendous pressure on manufacturing companies to cut costs. Many companies looked at the problem in two different lights, cutting costs or focusing on value.

Cutting costs has always been the easiest solution, because everyone knows price elasticity of demand is about as an important factor in selling your product as anything. When you sell something cheaper than your competitors you can “buy your way into the market”. The option of cutting costs also precipitated the exponential growth of a 24/7 workforce, machines.

Manufacturing companies were scrambling to reduce scrap rates, increase efficiency and decrease costs. With the latest generation of machinery and automation controllers, many of the previous production limitations were being eliminated. All of this was only possible because of the creativity and innovation of engineering.

The other component to competing in the global market as a US company was to focus on the quality of the product. Quality has long plagued many American industries, especially the automotive industry. Consumers were promised cheaper goods and better quality with foreign competition.

This was a call to action for many American companies in improving their quality standards, actually utilizing sophisticated quality programs (like TS 16949 in the automotive world) that more accurately dissect root causes and focus on strict tangible, quantifiable standards. This was something many of the infant overseas competitors could not guarantee.

As time progressed those overseas companies got more competent and they started having a real impact on the domestic labor market and outsourcing started becoming common vernacular in every industry. However, what doesn’t kill you makes you stronger and the one thing though that has always differentiated engineering from most other industries is innovation.

The manufacturing industry was adjusting to increasing foreign competition and outsourcing and then probably the worst thing that can happen to an industry already struggling happened, the 2008 financial implosion.

As many of the engineering graduates from the classes of 2007-2011 remember, it was very difficult to find a job during that time. It was even more devastating to mid-career engineers and engineers in their twilight years.

Companies were having substantial layoffs due to drops in demand and lack of liquidity provided by the banks. The banks essentially ceased lending to many smaller to mid size manufacturing companies, which devastated the industry. The already stressed manufacturing industry was being eviscerated in this economic disaster.

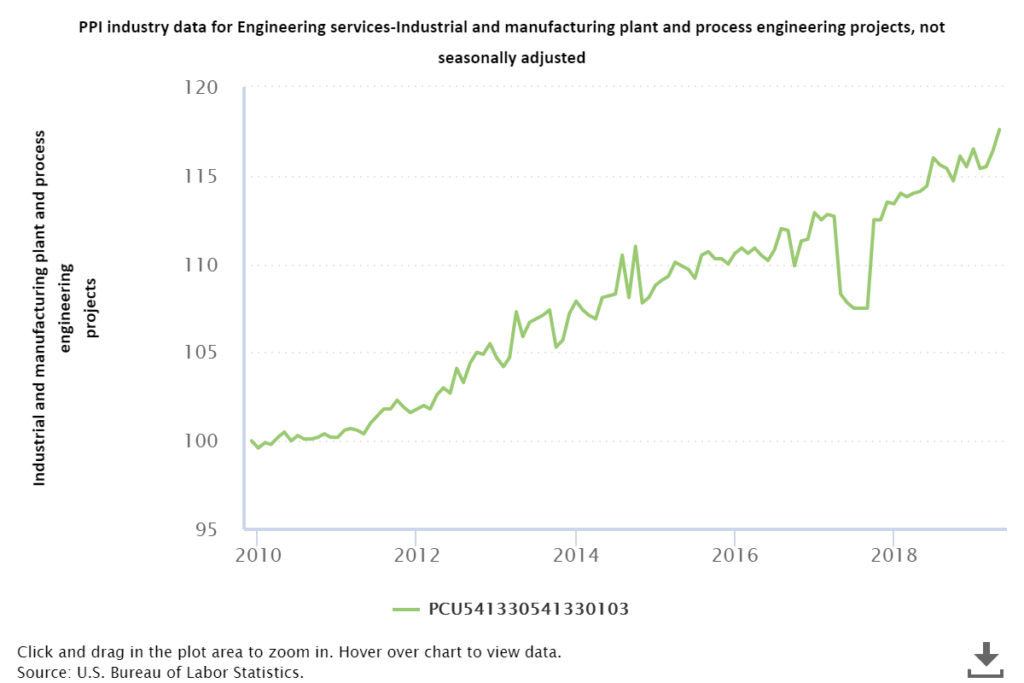

Courtesy of the US Bureau of Labor Statistics

As you can see in the chart attached above, the rate of growth and demand for engineering has been steady since 2010 with a small hiccup in 2017. With the resurgence in the economy, companies are beginning to bring back engineering related business to the US and a laser like focus on lean and automation leading the charge.

Although outsourcing was still a big factor in loss of jobs for machinists, laborers and molding related positions, I myself witnessed a resurgence in companies bringing back machine jobs, forging plants and other manufacturing related disciplines thought to be next to extinct domestically

I saw a very curious thing happening as well with foreign companies investing in US labor. Japanese and German companies, and several other foreign manufacturing powerhouses were building plants in the US and utilizing American engineering as the backbone for their success

Japanese companies, known for their contributions to modern lean practices and ability to build economic and well performing products with high value, were sharing their knowledge of wealth with American engineers. In my opinion one of the big problems with American made was quality, not innovation (which I believe is its biggest strength). With the promotion of lean manufacturing and utilizing quality programs to improve efficiency, made in America was building a name for itself in the global market.

The problem with many businesses still is that they devalue engineering, they look at only the cost side of things instead of the overall value that a great engineering team can bring to the table. Engineers are able to save companies tremendous amounts of money by efficiency improvements, design of product manufacturablity, innovation in process improvement and reduction of quality issues. In conjunction with this they bring the ideas of the future to fruition, by utilizing the advancements in science to the drawing board for conception.

My thought is demand for engineering jobs will continue to grow due to the need for innovative ideas and continued reduction of costs and improvement of efficiency. Coincidentally the Bureau of Labor Statistics shares my opinion and they have much more elegantly put it together in numbers (which all engineers love). So, without further ado lets look at those numbers

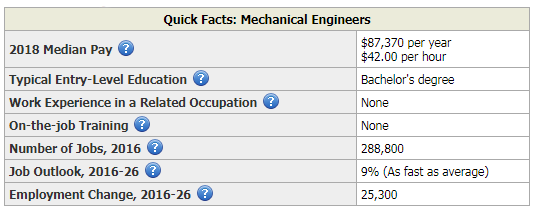

Courtesy of Bureau and Labor Statistics

As you can see in the chart, the outlook for the future of mechanical engineeng is pretty rosy at 9%. It makes perfect sense to me since most mechanical engineers are very versatile. I have seen ME’s doing PLC programming, process improvement, conceptual product design, facilities design, heck I even saw one running an IT department and doing engineering stuff (great guy btw).

The median salary 87K in my experience seems about right, when you take into account cost of living adjustments for different parts of the country. Salaries are going to be lower than the median in rural areas and the Midwest but higher to much higher on the west and east coasts in the bigger cities. Overall in my experience mechanical engineers are some of the most in demand engineering positions we recruit for and I concur with the BLS that that’s not going to change.

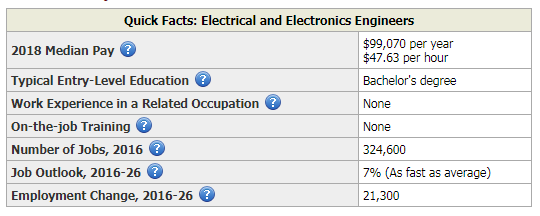

Courtesy of Bureau and Labor Statistics

Although the chart reflects a 7% growth, I think this could be potentially underestimating this discipline. Why do I feel this way? Everything in the modern factory is moving to automation, and you can’t talk about automation with out discussing controllers, robots and vision systems, etc. A good portion of the PLC engineers I place are EEs that learned to code and program either in school or at a job. Allen Bradley is the biggest player in the states and continues to proliferate in automating all facets of a modern manufacturing environment.

I don’t see this trend changing and I do see the demand for installing and supporting these control systems to continue to grow. The other component to this is the electrical design or schematics for the electrical supply to the equipment which is something else an EE is equipped to do. I know EE’s do more than controllers and electrical design, but I really like talking about PLCs.

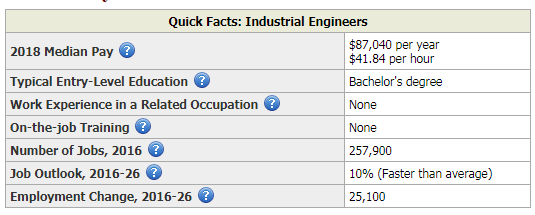

Courtesy of Bureau and Labor Statistics

Wow, 10% not bad for the IEs. IE’s are another group of engineers that are crucial to success of a company thriving in the global market. Since process flow and layouts are instrumental in making plants more efficient and cost effective, its no surprise that the future demand for industrial engineering is going to be high. I see a lot more industrial technology graduates as well and that seems to be another discipline that is in demand.

Courtesy of Bureau and Labor Statistics

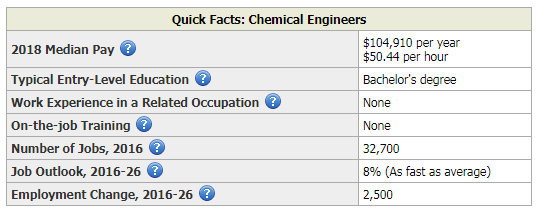

Congratulations to the ChemEs who have the highest median pay. The growth rate for chemical engineers doesn’t surprise me, although of all the engineering disciplines from my experience they seem to be in less demand. From what I have seen companies tend to pigeon hole them because they feel their skills lend to certain industries. So from that standpoint, the degree and experience isn’t as scalable as a ME or IE or even EE. With that said, there is still demand for them, its just more focused on niche industries than broad applications. I also want to say ChemE programs are some of the most difficult in engineering and its not that they couldn’t do other engineering roles, its just companies feel they are better suited for certain industries (feedback I have gotten).

Courtesy of Bureau and Labor Statistics

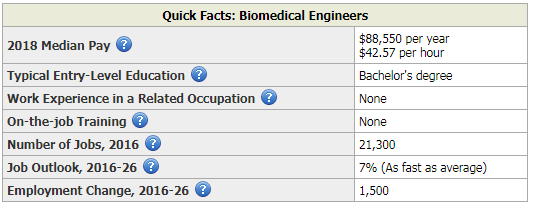

We have been involved in biotech for the last 8 years and although the industry is growing, I thought it would be bigger. I have a feeling with some of the M&As (mergers and acquisitions) of the big pharma players and small to midsize biotech startups that there will be more growth. Genomics and biomarker testing are going to continue to grow, especially in the oncology, hematology, CVD and dementia fields. There are so many amazing discoveries coming to the forefront and it something I want to discuss a lot further detail in another blog post.

Courtesy of Bureau and Labor Statistics

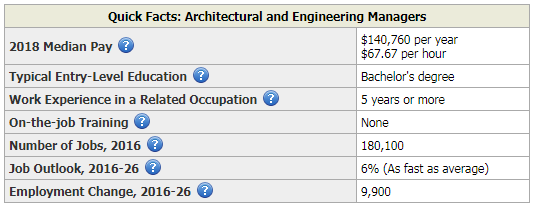

For all of you engineers that want to get into management or are already in management, the growth is still there but at a slower rate. It makes sense though because this figure doesn’t take into account executive level promotion opportunity that you would have in a larger company. From the best of my knowledge this is only taking into account strictly engineering supervisory or management roles, not corporate roles filled by engineers.

With that said, many engineers prefer not to get into management or they prefer to work in the capacity as a manager in engineering. From the thousands of engineers I have spoken with most get into engineering to design stuff or make something better. The science of engineering is very interesting and for a mind geared toward that, the business side just sounds awful.

Something that I thought was particularly exciting for engineers was a BLS cited statistic of average median salary of engineers vs average worker salary. Engineers average median income is TWICE that of the average worker bee….impressive. One other interesting bit the Bureau of Labor Statistics cited was the fastest growth discipline in engineering was going to be the future demand for Civil Engineering at 26%. Civil engineering will also account for 23% of the overall growth in the engineering industry.

So if you are looking for a high demand career in engineering, that certainly might be viable option. Unfortunately we do not recruit in the civil realm, so I just wanted to mention it without discussing something I know very little about. If you would like to learn more about what kind of jobs we recruit on check out our engineering positions/disciplines page. I think overall the Bureau of Labor Statistics information points to a lot of positives for the future demand for engineering jobs. Hopefully this information prompts more brilliant minds to pursue a career in engineering.